Allison Glick, Sayed Mohamed, Alex Saykali, Bruce Ye

For this project, I was tasked with simulating a one foot steel bar moving using motion analysis in SOLIDWORKS with the goal that it wouldn't topple over. I then had work three other students to make a physical prototype and test it against the simulation.

I designed my project with simplicity and size in mind. I wanted it to be easy to assemble with very few parts and to be as small as possible. I attached a wheel to the motor that would push the rest of the cart. I put a holder n the front for the motor and attached wheel while the back had two wheels on an axel going through the base. I put another wheel and axel for stability as the motor was not centered. I then added the bar on top of the platform, and using a series of mates that I suppressed later on for the simulation, I was able to get it centered.

Using the SOLIDWORKS Motion add-in, I was finally able to do a motion analysis of my project and find out how fast it can go without the bar toppling over, which was around 10 seconds.

CAD model of my project.

After the simulation was finished, Allison Glick, Alex Saykali, Bruce Ye and I were tasked with making a physical prototype that matched the simulation time. We came up with a pulley system and gear system to move the prototype. After some debilitation and in person testing, we settled on a gear system rather than a pulley to make the whole thing more compact and more reliable.

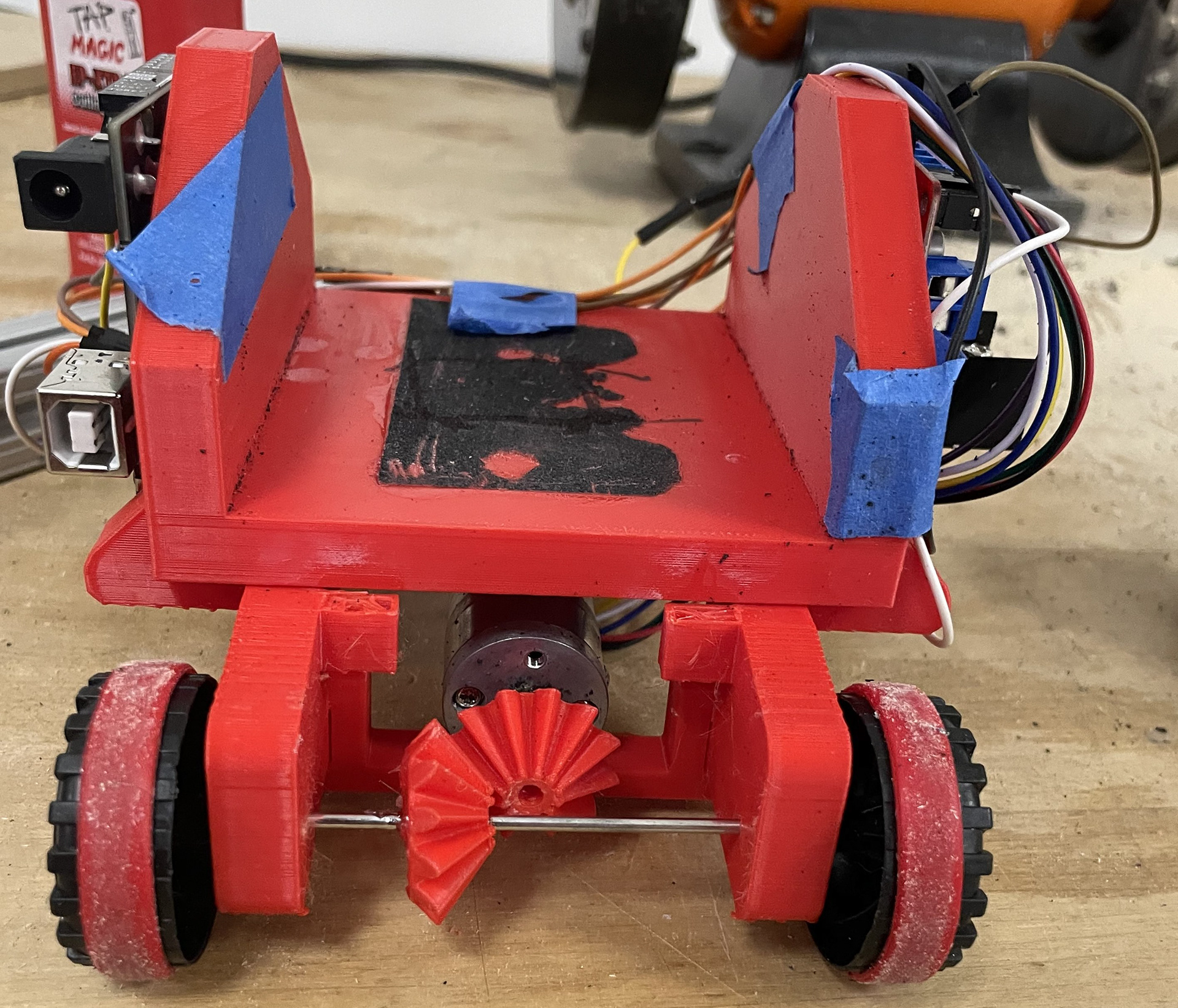

Back

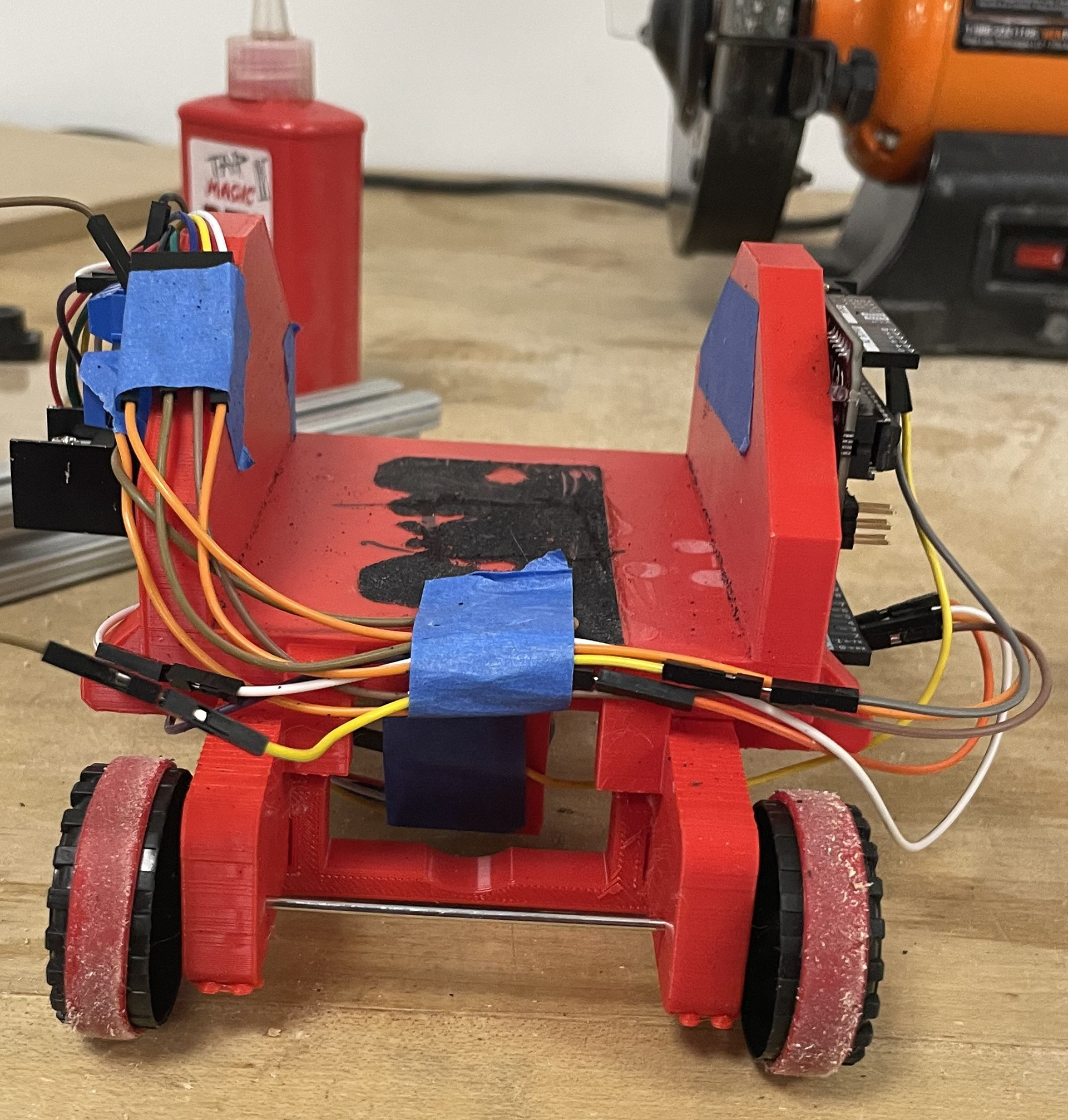

Left

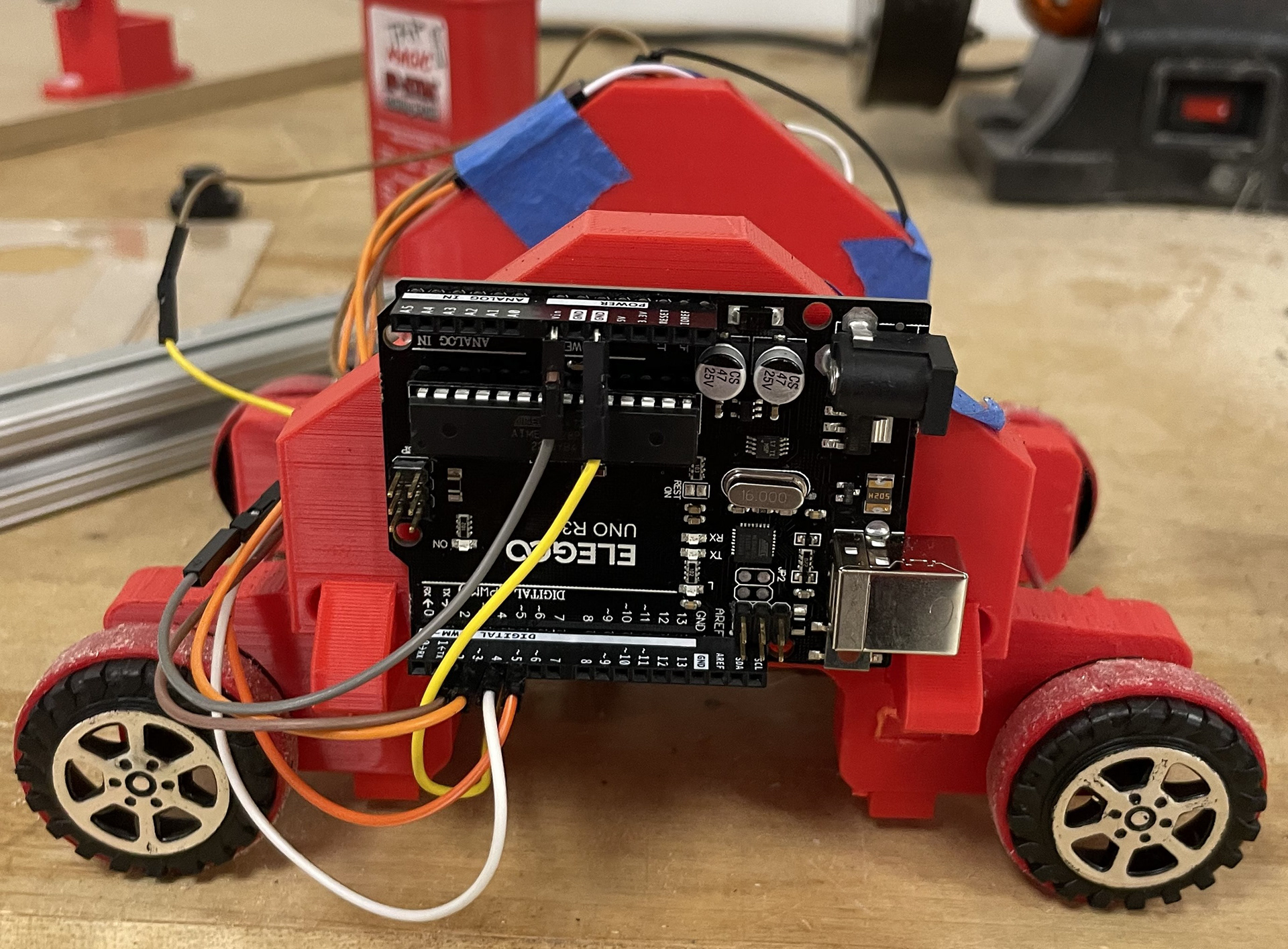

Front

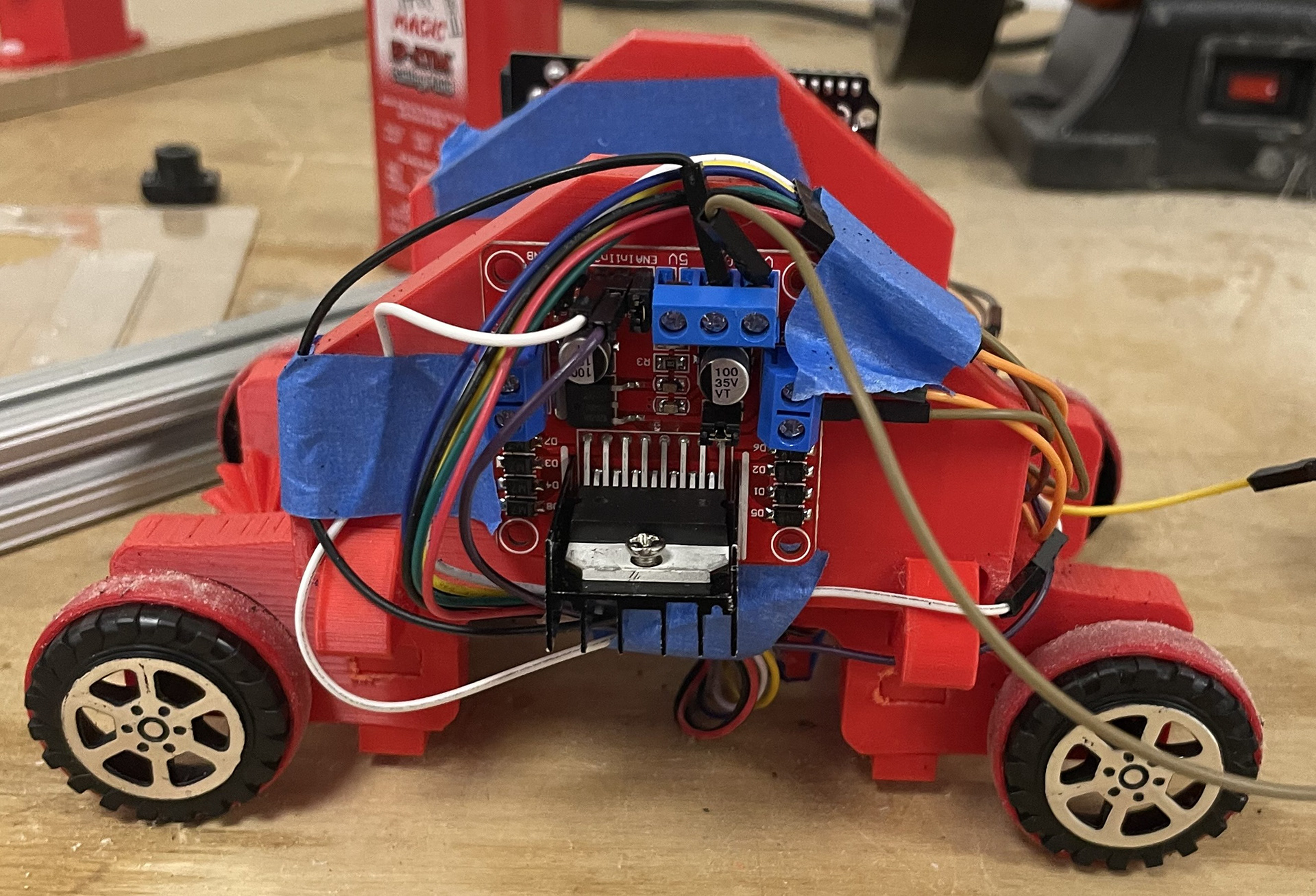

Right

We 3D printed parts from both Bruce's and Allison's base designs for the body of the prototype. We also used the provided metal axles and plastic wheels from our professor. We put silicone rubber bands on the wheels to increase friction and help it run more smooth. We also printed a two gear system; one gear was attached to the back axel while the other was attached to the motor. The design we picked had a designated spot for the motor already that lined it up with the back axle. An Arduino Uno was attached on the left wall of the base while the power amplifier was attached on the right side both using hot glue. These were used to power the motor. We secured the wires using masking and electrical tape to keep it out of the way of the wheels.

We then coded the Arduino to move the motor at specific speeds ever second. We were able to get the bar across ten feet in around 11 seconds without falling after a couple of trials. The unreliability of the prototype was suspected to be because we didn't allocate a specific place for the bar to sit and eyeballed the middle of the base. This would cause the bar to fall sideways. We could put side walls that helped with placing the bar and making sure it doesn't fall sideways.

This project helped me with strategizing and prototyping skills in a both individual and group setting. I was able to practice general engineering abilities with SOLIDWORKS, Arduino coding, and circuity as well as problem solving. I also learned new skills like motion analysis in SOLIDWORKS and 3D printing.

Final Project

Alex, Me, Allison, and Bruce pictured with the physical prototype